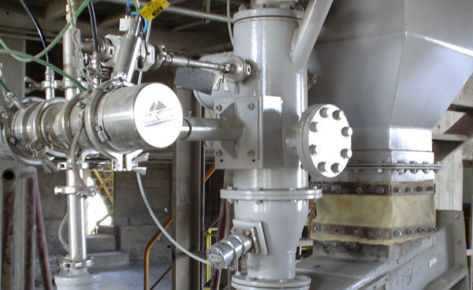

At line spectro-colorimeter

SpectrObserver

- Measure the colour of dry powder samples< 1mm with an outstanding precision

- Sequentially analyse representative samples collected by our sample takers

- Display the colorimetric standards and their trends on a touch screen and a PC

- Detect any drift of the ongoing production

- Trigger alarms on events and record all relevant data

- Control final quality

Main advantages

- High measurement frequency: up to one sample / 6 mn

- Very high precision due to spectral analysis

- Better responsiveness compared to the laboratory analysis

- Full traceability of the production

- Constant quality compliant with client specification

Related products

In the same range…