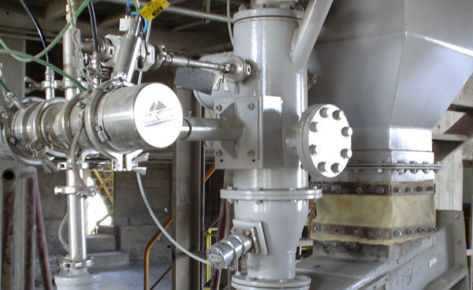

At-line particle size distribution analyzer

PartSizer

- Measure dry particle size in the range of 63µm and 4mm

- Sequentially analyse samples prepared by our automatic sample takers

- Use the same vibratory sieving methods as the laboratory

- Detect any non conformity or production drift

- Trigger alarms on non conformity and record data

- Display the distribution in size of the samples taken on various production lines

Main advantages

- Continuous quality control

- Ensure compliance with client specification

- Full traceability of the production

- Better responsiveness compared to the laboratory analysis

Related products

In the same range…