Our devices dedicated to colour control, non-conformity detection or particle size measurement are perfectly integrated into production lines. Our high level of accuracy combined with our communication skills allow us to meet the reliability and speed requirements of Industry 4.0

Our loading spouts and trolleys help increasing loading rates while reducing dust emissions. By breaking up lumps in materials, our lump breaker helps flows and prevents any blockages in the process

Our solutions allow the collection or sampling, transport, preparation, storage and analysis of samples at the different key stages of the manufacturing process and this, according to the different requirements (process or quality control, material balance sheet, business transactions, etc.)

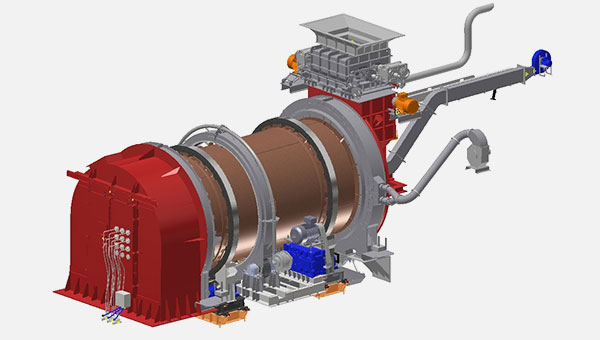

Efficient sealing of your rotary kiln (calciner or dryer) stabilizes your process, reduces fuel & power consumption and thus contributes to the reduction of your plant’s CO2 emissions. Our inlet and outlet sealing solutions meet all these requirements and provide a quick and sustainable return on investment.

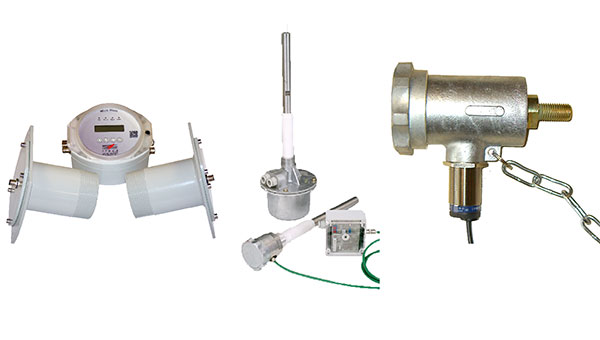

A complete range of level detectors, level measurement sensors and operation control sensors With more than 40 years of experience in instrumentation, our solutions are recognized as robust and reliable. They perfectly meet the highest requirements of our customers.

This solution is dedicated to white cement plants seeking to optimise the quality of their clinker, particularly in terms of its colour and uniformity.

This mobile machine, whose configuration is customised to the grinding medias of each factory, allows an efficient and fast sorting while eliminating fragments and dust as well as broken or deformed balls. It reduces mill downtime and eliminates the need for the plant to stock a spare balls load.