our customer tailored solutions

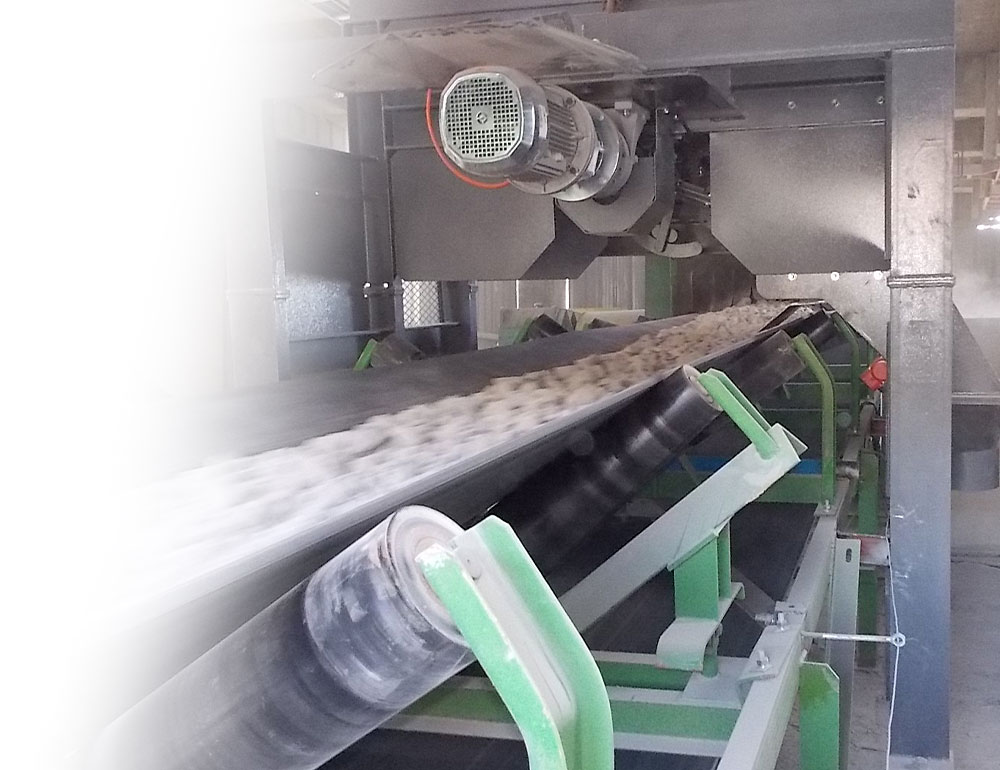

Our expertise is based on the design and manufacture of systems to optimize our customers’ processes.

The equipment we design, belong to the decision making process and plant operation as they improve product quality while reducing production costs and environmental impacts.

our customer

tailored solutions

Our expertise is based on the design and manufacture of systems to optimize our customers’ processes.

The equipment we design, belong to the decision making process and plant operation as they improve product quality while reducing production costs and environmental impacts.

Specific Applications

events

16-19 April 2024

CAIRNS, AUSTRALIA

From April 28 to May 2, 2024 IEEE-IAS/PCA, Cement Conference, Denver (Colorado), USA

5-8 May 2024, 8th ESST Conference, European Society for Sugar Technology, Wien, Austria

23-24 May 2024

Post Campaign Conference of Polish Sugar Technologist, Warsaw, Poland