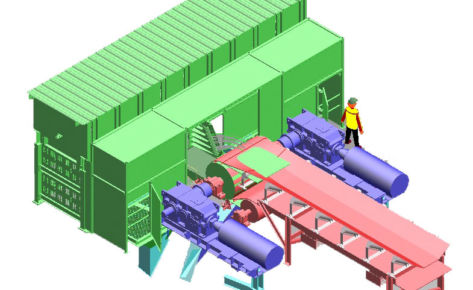

Linear Cutter Sampler

PTR

The Linear Cutter Sampler PTR is designed in compliance with Sampling Theories and Sampling Standards. The PTR sampler is used to collect representative samples at discharge of conveyor belt. The cutter travels through the whole stream of product at a constant speed and collects a full cross-section.

Iteca Socadei also proposes complete sampling stations.

Main advantages

- Compliant with TOS (Theory Of Sampling) and Sampling standards

Related products

In the same range…