nos solutions sur-mesure

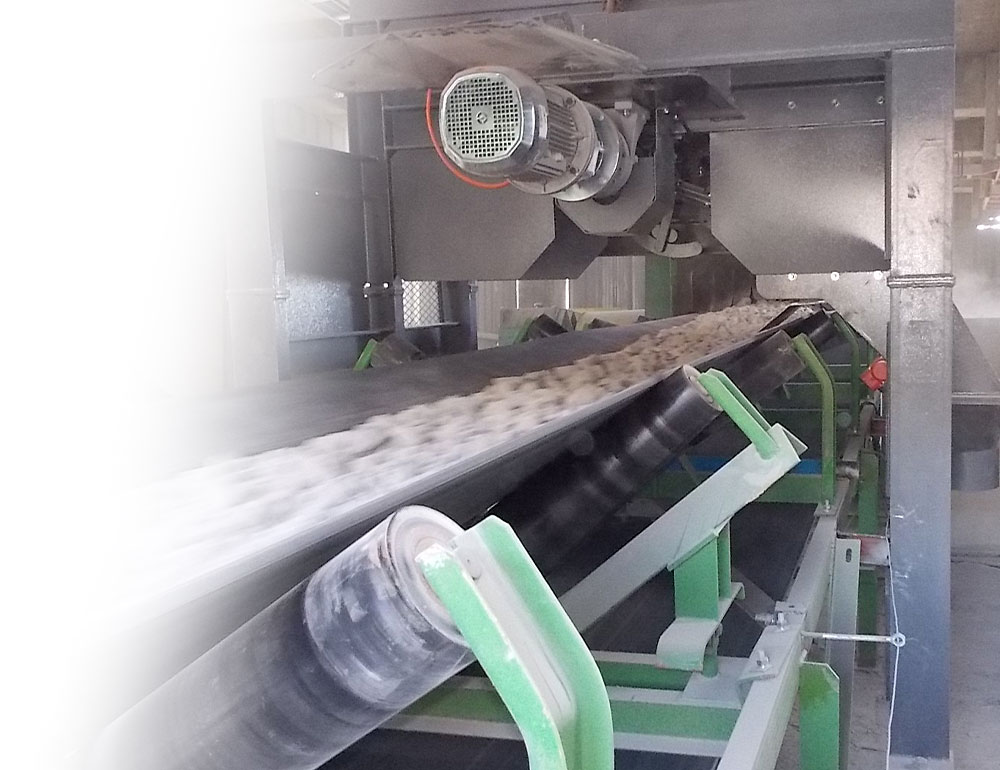

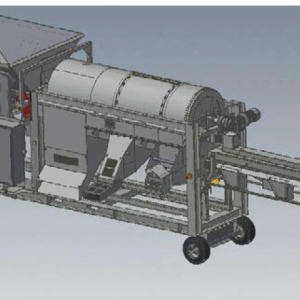

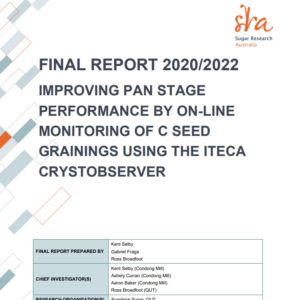

Notre expertise se base sur la conception et la fabrication de systèmes permettant l’optimisation des process de nos clients.

Les équipements que nous concevons sont des éléments essentiels dans les processus de prise de décision et le fonctionnement des usines puisqu’ils permettent d’améliorer la qualité produit tout en réduisant les coûts de production et les impacts environnementaux.

nos solutions

sur-mesure

Notre expertise se base sur la conception et la fabrication de systèmes permettant l’optimisation des process de nos clients.

Les équipements que nous concevons sont des éléments essentiels dans les processus de prise de décision et le fonctionnement des usines puisqu’ils permettent d’améliorer la qualité produit tout en réduisant les coûts de production et les impacts environnementaux.