Technicien Installation, Mise en service et SAV (H/F)

Par ITECA MP Carrières

Charge d’affaires en Mecanique

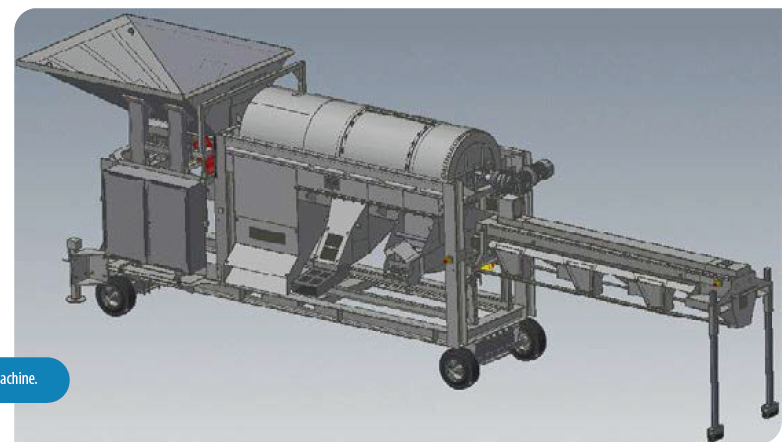

GOOD BALL SORTING = HIGH MILL EFFICIENCY

Les joints de fours.

Par ITECA MP Articles Département Couleur & Vision

Description des différents systèmes en ligne de détection des contaminants dans le process sucrier

Par ITECA MP Articles Département Couleur & Vision

Description des différents systèmes en ligne de détection des contaminants dans le process sucrier

Les avantages de systèmes d’analyse en ligne au niveau du contrôle Process

L’impact d’un joint d’entrée de four étanche sur la consommation électrique

Article collectif donnant une vision précise des arguments économiques pour l’échantillonnage représentatif.

La Fleur de sel, apparaît à la surface des bassins de cristallisation (appelés œillets) sous la forme d’une fine pellicule opalescente.